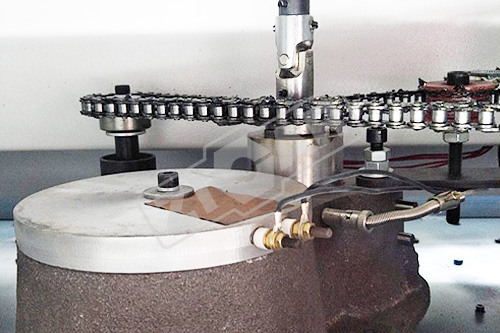

Edge banding with hot melt glue on edges in rolls and strips on shaped panels.

Simply essential and functional. Designed to be economic, reliable and practical machine for the edge banding of straight, curved and bevel panels.

share to:

Edge banding with hot melt glue on edges in rolls and strips on shaped panels.

Simply essential and functional. Designed to be economic, reliable and practical machine for the edge banding of straight, curved and bevel panels.

| Model | MF515A | MF515B | MF515C |

| Type | with rotary auxiliary table | Basic Model | with auxiliary table |

| Panel Length | Min. 150mm | Min. 150mm | Min. 150mm |

| Panel Thickness | 10 -55mm | 10 -55mm | 10 -55mm |

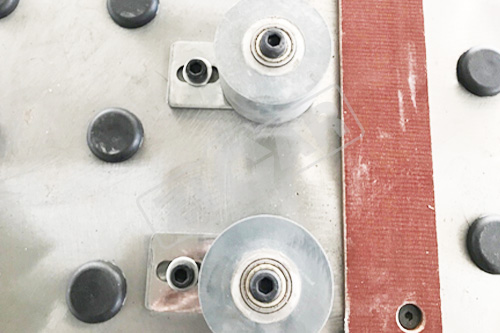

| Edge Thickness | 0.4-3mm | 0.4-3mm | 0.4-3mm |

| Feeding Speed | 1-7m/min | 1-7m/min | 1-7m/min |

| Working Pressure | 0.4-0.5Mpa | 0.4-0.5Mpa | 0.4-0.5Mpa |

| Weight | 192/ 230kg | 168/ 200kg | 175/ 210kg |

| Motor Power | 2kw | 2kw | 2kw |

| Overall size | 1110*830*1000mm | 950*750*1000mm | 1000*830*1000mm |

| Packing Size | 1150*880*1100mm | 1050*830*1100mm | 1050*890*1100mm |

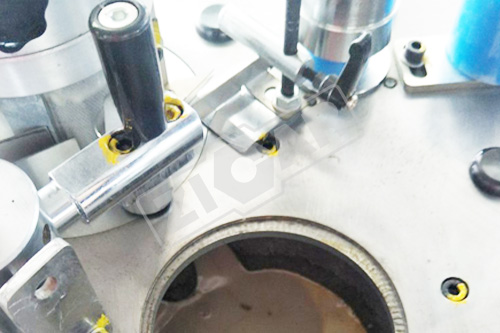

1.The Machine is a manual-operation model, with downward glue pot, can be double-sided gelatinized.

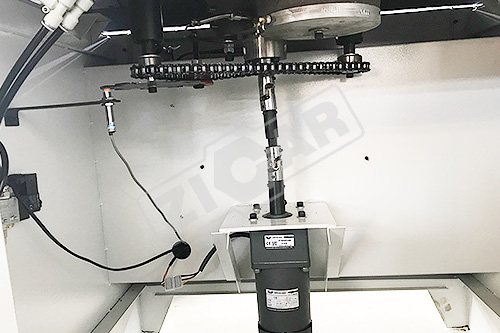

2.The machine adopts Taiwan Delta frequency transformer, which can stepless adjust the band feeding speed and glue shaft rotation speed.

3.Equipped with length control system, the edging band will be automatically cut according to set-up length, which greatly reduces the waste of the edging band.

4.The working table can be tilt from 0-60, suitable for bevel edge banding .

Functions

Rotatable extension table (0-60°), suitable for bevel edge banding .

Please fill in the form with your details and we will get back to you as soon as possible.

Frequently Asked Question

What kind of machine you offer?

How to choose suitable machine?

How long is the machine leading time?

Oversea Service (Technical Assistance)

Could you ship machines to my country? If possible, could you make DTD?

How long is guarantee?

Where and how long can we get the replacement parts?

Payment Terms

Could you make the machine according my own requirements?