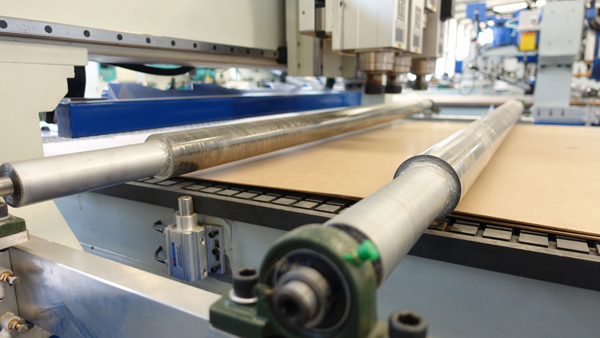

1.ALL-WELDED STEEL BASE:

The bed is made by CNC metalworking centers, which makes it possible to obtain high accuracy and quality when processing workpieces of any size.

2.STEEL PORTAL:

Made of rectangular steel pipes and reinforced, it provides a high degree of rigidity, resistance to static and dynamic loads.Portals frame is made by CNC metalworking centers. Guaranteed high accuracy and quality better than the cheap lightweight aluminum portals.

3.SKEWED GEARS GEAR – RACK AXIS X –Y:

The teeth in helical gears are loaded gradually as they enter the engagement zone, at least two pairs of teeth are always

in engagement. These factors determine the smooth operation of the helical gearing, as well as the reduction of noise and

additional dynamic loads in comparison with the spur gearing.

4.AIR-COOLED INDUSTRIAL ELECTRIC SPINDLE “HQD” (6kw/4.5kW – 18,000 RPM):

The design and components of this electrospindle are 100% identical to those of the world’s leading spindle manufacturer – HQD. Rotation frequency (18,000 rpm) and power (6kw/4.5KW) make it possible to process wood parts, as well as chipboard, MDF, plastic, acrylic glass and other materials.